If you want to improve your home’s energy, efficiency. It’s important to know if foam insulation is a good choice.

How it can be installed in different climates and humidity levels, and how it compares to other options. Is this also good for soundproofing along with thermal insulation?

Learn about the types of residential foam insulation and their unique properties to make the best choice.

What Is Foam Insulation?

Foam insulation is an airtight material that blocks outside temperatures from affecting your home’s interior.

It acts as a barrier, protecting your home from the environment, maintaining comfort, and preventing energy loss. It forms an air barrier that seals gaps, cracks, and cavities in your home’s structure.

It comes in various forms, like sprays, boards, and injections, making it suitable for different parts of the home. This versatility makes it a convenient and affordable choice for homeowners.

Types of Residential Foam Insulation

There are five primary types of foam insulation commonly used in residential settings:

1. Spray Polyurethane Foam (SPF)

Spray polyurethane foam is the most commonly used and effective form of insulation.

It comes in a liquid form like paint and is applied with the help of a brush on walls, roof, attic etc. It expands into foam, filling gaps and voids of walls, thereby stopping the flow of air.

Spray foam comes in two varieties:

- Open-Cell Foam: This type has a lower density and is more affordable. It’s ideal for interior walls and attics where moisture resistance isn’t critical. Open-cell foam also provides excellent soundproofing due to its porous structure.

- Closed-Cell Foam: This denser option offers a higher R-value (thermal resistance) and acts as a moisture barrier. It’s suitable for exterior applications like basements, crawl spaces, and roofs. Closed-cell foam also adds structural strength to walls and roofs.

Applications:

- Sealing air leaks

- Insulating hard-to-reach spaces

- Improving overall energy efficiency

- Reinforcing structural integrity

2. Pour Polyurethane Foam

Pour polyurethane foam is similar to spray foam but differs in application. Instead of spraying, the foam is poured into place, making it particularly effective for:

- Closed-Cell Pour Foam: This dense and moisture-resistant foam is ideal for insulating concrete blocks and masonry. Its slow expansion ensures thorough coverage without overfilling.

- Open-Cell Pour Foam: This less dense option is cost-effective and works well for residential wall cavities where excessive moisture isn’t a concern.

Applications:

- Filling concrete blocks

- Retrofitting existing walls

- Insulating hard-to-access cavities

3. Can Foam

Can foam, often referred to as “foam-in-a-can,” is a single-component foam sold in pressurized canisters. It expands upon application, making it a convenient choice for small projects.

Best For:

- Sealing gaps, cracks, and holes

- Insulating around windows and doors

- Fixing minor air leaks

Can foam is easy to use and ideal for DIY projects. However, it’s not suitable for large-scale insulation due to its limited coverage and higher cost per unit.

4. Injection Foam

Injection foam is a unique type of insulation designed for retrofitting older homes. Unlike other foams, it doesn’t expand significantly, which prevents damage to existing structures.

Features:

- Made by combining resin, water, and a foaming agent

- Consistency similar to shaving cream, allowing it to flow easily into tight spaces

Applications:

- Insulating existing walls without removing drywall

- Filling narrow cavities in older homes

- Enhancing energy efficiency in remodeled spaces

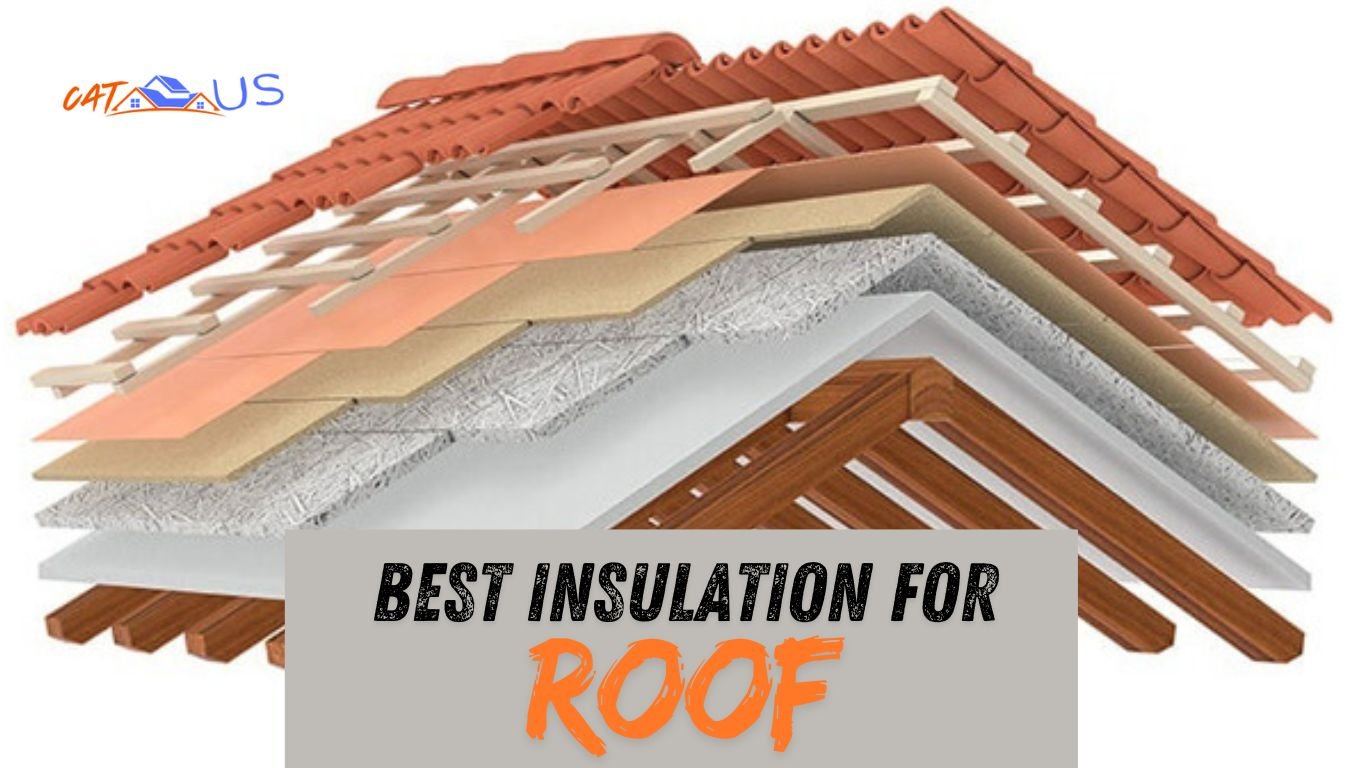

5. Foam Board Insulation

Rigid foam boards, also known as foam panels, are a durable and versatile option for residential insulation. They come in various materials, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (Polyiso).

Best For:

- Insulating basements, attics, and exterior walls

- Creating a thermal barrier on flat surfaces

- Improving energy efficiency in large open areas

Advantages:

- High thermal resistance (R-value)

- Durable and long-lasting

- Lightweight and easy to install

Comparing the Types of Foam Insulation

| Type | Density | Moisture Resistance | Best Applications |

| Spray Polyurethane (Open) | Low | Moderate | Attics, interior walls |

| Spray Polyurethane (Closed) | High | High | Roofs, basements |

| Pour Polyurethane (Open) | Low | Moderate | Residential wall cavities |

| Pour Polyurethane (Closed) | High | High | Concrete blocks |

| Can Foam | Variable | Moderate | Small repairs |

| Injection Foam | Variable | Variable | Retrofitting existing walls |

| Foam Board | Rigid | Moderate | Basements, attics |

Advanced Features and Benefits

1. Thermal Performance

Foam insulation provides superior thermal resistance compared to traditional materials like fiberglass. Closed-cell foam, in particular, offers high R-values, ensuring efficient temperature regulation throughout the year.

2. Moisture Management

Closed-cell spray and pour foams act as effective moisture barriers, preventing water infiltration and reducing the risk of mold growth. This makes them ideal for damp areas like basements and crawl spaces.

3. Soundproofing

Open-cell foam excels at absorbing sound, making it a great choice for creating quieter indoor environments. It’s often used in walls and ceilings to minimize noise transmission.

4. Structural Reinforcement

Closed-cell foam adds rigidity and strength to structures, enhancing durability and resilience. This feature is particularly valuable in areas prone to high winds or seismic activity.

5. Eco-Friendly Options

Many foam insulation products now incorporate eco-friendly technologies, such as water-blown agents and recycled materials, reducing their environmental impact.

Environmental Considerations

While foam insulation is highly effective, it’s essential to consider its environmental footprint:

- Chemical Emissions: Some foams release volatile organic compounds (VOCs) during application. Opt for low-VOC or water-blown alternatives.

- Recyclability: Foam boards and other rigid products require proper disposal to minimize landfill waste.

- Sustainability: Choosing eco-conscious products and certified installers can reduce environmental harm.

Installation Tips

To ensure the best results, follow these guidelines for foam insulation installation:

- Hire Professionals: For complex applications like spray or injection foam, professional installation ensures proper coverage and quality.

- Follow Safety Protocols: Always wear protective gear, including gloves and masks, to avoid exposure to chemicals and irritants.

- Assess Your Needs: Evaluate the specific requirements of your project to choose the most suitable type of foam insulation.

Additional Applications of Foam Insulation

Foam insulation isn’t just for walls and attics. Here are some additional uses:

- Pipes and Ducts: Insulating pipes and HVAC ducts with foam can prevent energy loss and condensation.

- Garage Doors: Foam boards are a popular choice for insulating garage doors, improving energy efficiency and reducing noise.

- Floors: Spray foam can be applied under floors to enhance thermal resistance and minimize drafts.

My Experience with Foam Insulation

Having worked on multiple home insulation projects, I’ve seen the transformative impact of foam insulation firsthand. One notable project involved retrofitting an older home with injection foam.

The homeowners were delighted with the improved comfort and lower energy bills. Foam insulation’s versatility and effectiveness make it a reliable choice for both modern and traditional homes.